Supporting US Troops for More Than 100 Years

When America entered World War I in 1917, conditions on the Western Front horrified U.S. commanders. The trenches were wet and damp, and the weather was often very cold. Perfect conditions for trench foot, an infection that causes pain, swelling, and often gangrene.

General John J. Pershing, commander in chief of the American Expeditionary Force, was so concerned about the problem that he supervised the design of waterproof boots to protect the feet of Army soldiers and Marines. And the odds are many of them wore leather made in Red Wing, Minnesota by S.B. Foot Tanning Company, founded in 1872 and owned by Red Wing Shoe Company since 1986.

“There are records stating that military boots were made with S.B. Foot leather back in World War I, sometime between 1914 and 1918,” shares Lori Hyllengren, laboratory manager and 46-year employee. She speculates the company’s leathers may have been used as early as the Spanish American War in 1898.

WWII - New Tactics Demand New Boots

It was during World War II, however, that leather production for the U.S. Armed Forces really took off. The war saw new weapons and tactics which required changes in footwear. “We were needed by our government to make leather to support the war effort,” says Hyllengren.

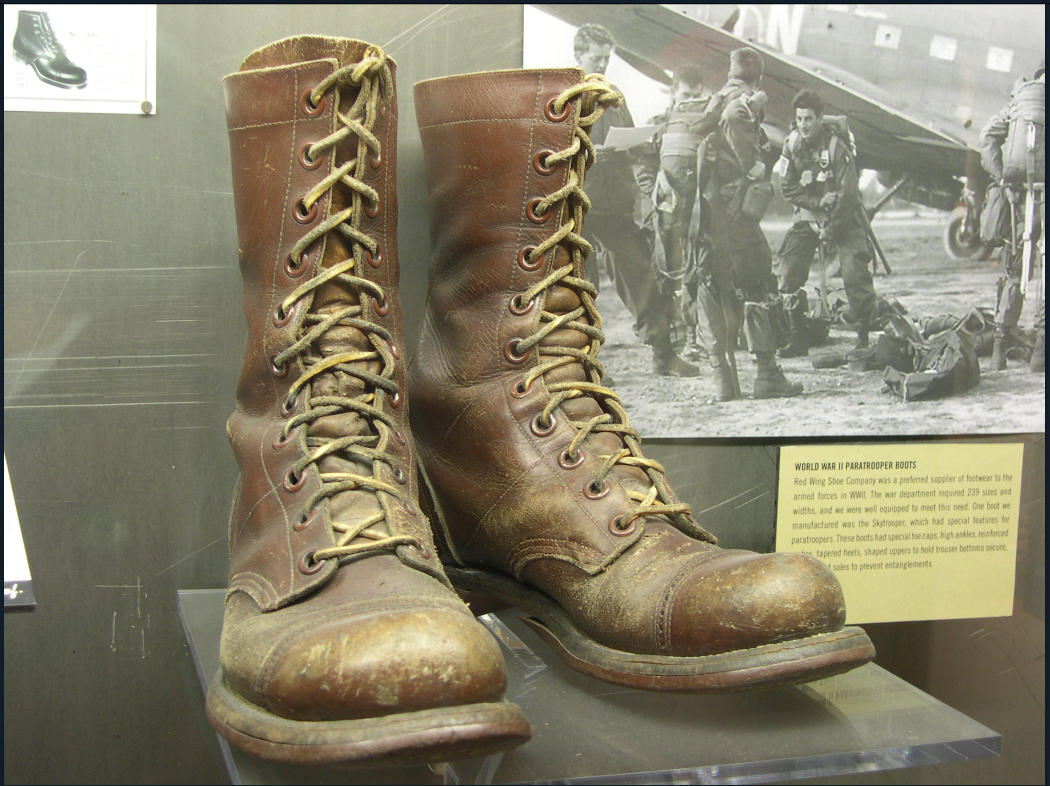

Paratroopers, for example, needed boots to help them survive the shock of a parachute landing, yet still, allow flexibility and durability for infantry fighting. Red Wing Shoe Company developed its famous “Skytrooper” jump boots, which were prized by airborne forces for their quality and comfort. S.B. Foot developed the leather for the boot to provide strength and suppleness.

S.B. Foot did so well, on September 8, 1944, the company received the “E for Excellence” flag by the War Department for its consistent quality and meeting the demands placed on it by the war effort. It was one of only five percent of defense contractors to win this coveted award.

(L-R) Foot, EH Sr. (Ed); Matson, Lieutenant Colonel RH; Garrity, Sgt.; Gage, Colonel John N.

Photo Courtesy of Red Wing Shoe Co, Inc. Corporate Archives

A Tradition of Innovation and Service Continues Today

The Pentagon turned to the company during the Vietnam War to develop boots to withstand the tropical climate. Before Vietnam, troops did not have much exposure to jungle-like conditions. S.B. Foot created the waterproof “tropical combat” leather to once again protect U.S. soldiers.

Since then, S.B. Foot Tanning Company has provided enough leather to produce approximately 60 million pairs of boots. “And that’s for the military just since Vietnam,” adds Doug Gilles, plant manager and 30-year employee. “That doesn’t include work boots and so forth.”

The reason S.B. Foot leather is popular with the military is because of the innovation and craftsmanship that goes into every hide. Hyllengren sits on a Department of Defense footwear committee that develops and enforces standards for leatherware used by the military.

“I help them because leather isn’t their business, and if there’s anything I can do to help ensure that the leather going into these boots is what it needs to be, I want to help,” she says. In 2016, she received an award from the American Society for Testing & Materials (ASTM) for her service, dedication, and technical expertise of leather.

Today, S.B. Foot is developing a new, lighter-weight leather. This will help the Department of Defense take even more weight out of boots—adding flexibility while retaining durability. Plans call for the new leather to go into boots starting at the end of 2022. “I am proud that we are instrumental in developing this,” says Hyllengren. “Ultimately, it’s going to give all the servicemen and servicewomen a better boot.”

The Best Leather Takes Time … and Care

Leather making starts with raw hides. From Texas to Minnesota, hides are sent through a process called “bluing” which preserves the hides and stabilizes the proteins they contain. The hides then come to S.B. Foot, where they are inspected for quality and grading. Hides destined for the military must also meet stringent thickness and weight specifications.

“Then they go into our dyeing process,” Gilles explains, “and that takes about 12 hours for 150 to 160 sides. They go into a big mixer, and that’s where we get the color and other properties to make it waterproof. All of our military leather is waterproof, so that’s why it takes a little bit longer,” he adds.

A series of steps to dry the hides follow, and then the hides are stretched to maximize yield. These reduce the moisture in a hide from as much as 54 percent down to 14 percent, which is “ideal” according to Gilles. The hides are then buffed on one side to give the leather a bit of nap. The final steps include quality control inspections before shipping. The entire process takes up to four weeks.

Doing Our Part for Our Country

In 2022, S.B. Foot Tanning Company will celebrate its 150th anniversary. Its long legacy of being the largest supplier of leather used in military footwear is much to be proud of.

“It’s hard for me to believe what they [servicemembers] have to go through sometimes,” Gilles says. “I take a bit of pride just knowing that we can help them out and try to give them a little bit of comfort because they’re on their feet, for a run or a march, or whatever they’re doing.”

As the company looks forward to this Veterans Day on November 11, 2021, and its sesquicentennial in 2022, no one can express its pride in serving our military better than Mark Urdahl, President and CEO of Red Wing Shoe Company:

“We are a proud American company supporting the men and women who serve our country. We will continue to develop leather and services to support whatever needs and desires that the U.S. military has for our soldiers operating across the world. We will react to whatever situation as needs arise.”

Photo courtesy of Red Wing Shoe Co., Inc. corporate archives